VUL-CON® SECTIONAL VULCANIZING PRESS

Design Features

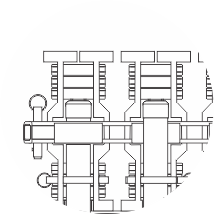

- Lightweight compact design for easy transport

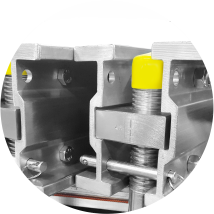

- Includes flush valves and inset bolts/nuts connecting the traverse bars

- All electrical systems are CE, CSA and UL approved

- Durable for use in harshest of environments

- Pressure bolts pass through the cross beam profile for a high level of safety

- Exact temperature regulation via an electronic control box

- Even pressure distribution across the splice area.

- Vulcanizing temperature is uniform and accurate.

- Automatic features for setting the temperature and curing time

- Standard sizes are available (custom size upon request)

Product Specifications

Material – High Grade Aluminium

Platen Bias – 17° degree, 22° degree, rectangle or any other on request

Control Box – Automatic process

Power Voltage – 220V, 380V, 400V, 415V, 440V, 480V, 525V or any other on request

Heating – Electric shielded resistance or silicone elements

Vulcanizing Temperature – 0-392°F (0-200°C)

Cooling – Water or air cooled

Part Numbers

This is a custom ASGCO® product, for more information contact us.